Laser cutting is one such new manufacturing technology in which a laser beam is focused to cut, engrave or shape any material with a precision beyond imagination. The technology has transformed industries including construction and automotive to fashion and design among others in its accuracy, speed and versatility like none before. It could be either cutting complex shapes out of metal or creating fine designs out of wood or acrylic, laser cutting provides nice clean cuts that could not be made with the other traditional methods of cutting. Its effectiveness and the quality of work has made it an indispensable tool in the modern world of great production and new design.

How Laser Cutting Works

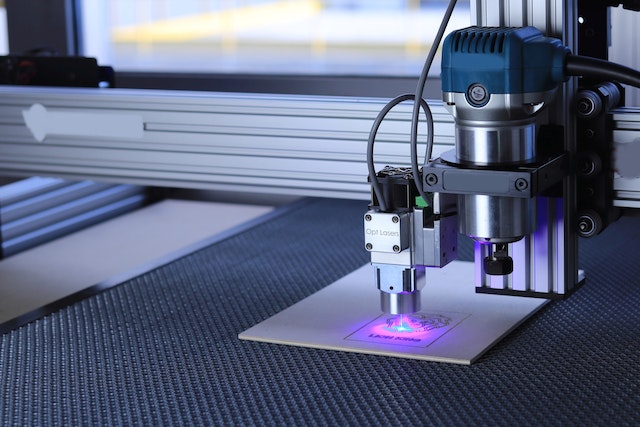

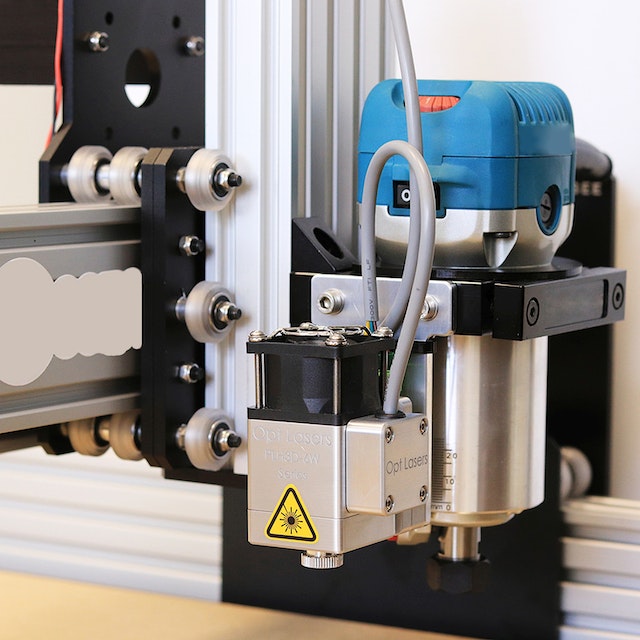

Laser cutting works on the principle of releasing a high-intensity beam of light on a substance, which produces a large amount of heat that melts or burns or evaporates the surface. Computer numerical control (CNC) technology controls the laser beam and thus ensures precise movements and repeatability. This enables accurate cuts and detailed designs even on complicated parts or thin material. The process can work on a number of materials such as metals, plastic, glass, wood and textiles. The fact that it needs minimum physical handling makes laser cutting Melbourne less likely to cause damage or distortion resulting to smooth edges and professional works each time.

Advantages of Laser Cutting

Laser cutting is very precise and this is one of its key benefits. Laser beam is capable of creating very fine cuts thereby it is perfect in creating patterned designs and customized designs. It is also very efficient-cutting is quick and probably less or no post-processing is needed and this saves time and wastes reduced. Laser cutting is not as limiting as conventional approaches because it can easily alternate between materials or designs without the use of tools. Also, it is ecological, since it produces minimum waste materials, and consumes less energy than the older methods of cutting. These advantages render laser cutting as an option of choice to industries that place value on precision, innovativeness and durability.

Laser cutting has found use in the following applications.

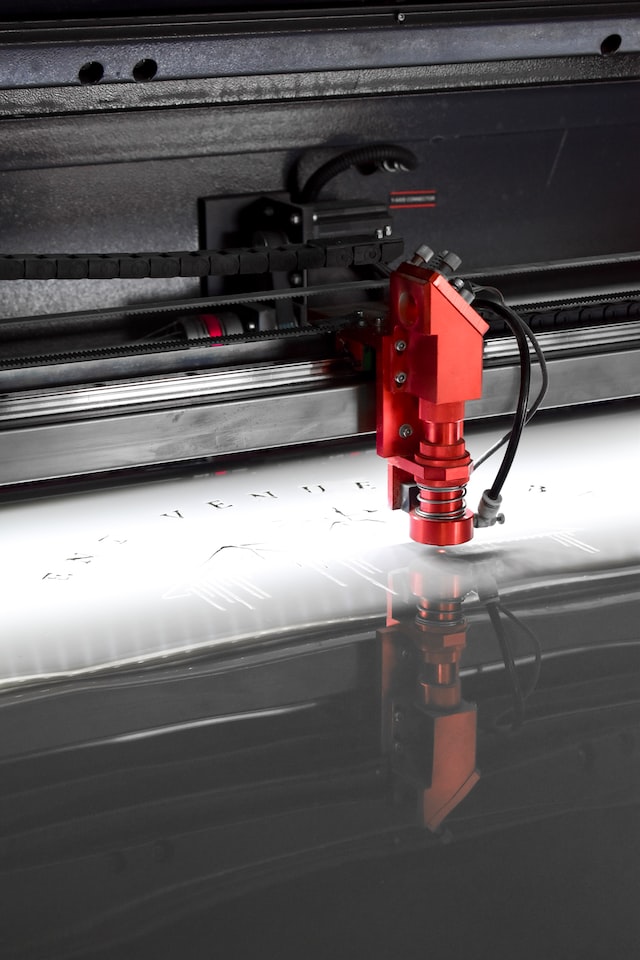

Laser cutting has a large variety of applications. In the production industry, it assists in producing parts as machine, electronics and car machinery. It finds application in architecture and construction to manufacture decorative panels, signage and tailor-made metalwork. Laser cutting is applied in the work done by artists and designers to create jewelry, sculptures, and fashion accessories. There are also uses of the technology in education and small-scale businesses where the technology is used to prototype and custom engrave. As the technology is constantly evolving, laser cutting grows its usage more, and it is a useful technology in industry, as well as creativity.

The ideal combination of technology, precision and creativity is laser cutting. It has made it possible to produce high quality results at speed and efficiency and this has made it a foundation of modern design and manufacturing that will define the future of the production process one beam of laser at a time.